Online Physics Papers

Online Physics Papers

Cryogenically Cooled Multiple-Substrate Holder for High

Vacuum

A. Chaiken and E.C. Honea,

Lawrence Livermore National Lab

Livermore, CA 94551

W.S. Rupprecht,

W.S. Rupprecht Consulting

Company

Fremont, CA 94539

S. Torres and R.P. Michel,

Lawrence Livermore National Lab

Livermore, CA 94551

Published as Rev. Sci. Instr. 65, 3870

(1994).

Abstract:

A novel design is presented for a cryogenically cooled

multi-substrate sample holder for thin film deposition in

high vacuum. The cryogen flows through tubing soldered onto a

fixed copper plate, while the substrates are mounted on a

separate tray which is supported by a linear/rotary-motion

feedthrough. By lowering the substrate tray into firm contact

with the copper plate, we can achieve substrate temperatures

as low as 120 K.

A common difficulty in the mechanical design of high vacuum

systems is reconciling rotary or linear motion of a sample

with simultaneous heating or cooling. While there are

commercially available solutions to this problem for a single

substrate, the difficulty is compounded when the user wants

to manipulate multiple heated or cooled samples without

breaking vacuum.

Substrate cooling is necessary in order achieve sharp

compositional gradients in multilayer films composed of

reactive materials. For example, multilayer films composed of

Fe and Ge which were deposited onto nominal room temperature

substrates were found to be non-magnetic and poorly

layered.[1] On the other hand, the deposition of several

multilayers without breaking vacuum is highly desirable for

reasons of reproducibility. In our design, the sample holder

has been split into two parts in order to accommodate both

substrate cooling and the interchange of multiple substrates:

a stationary tray to which cooling lines are brazed, and a

moving tray on which the multiple substrates are mounted. In

order to cool a substrate, the moving tray is pressed firmly

against the stationary tray, and liquid nitrogen is allowed

to flow through the cooling lines. When the deposition is

finished, the user can change substrates by raising the

moving tray and then rotating to the new substrate position.

The moving tray is then lowered with the new substrate in

place over the aperture in the stationary tray.

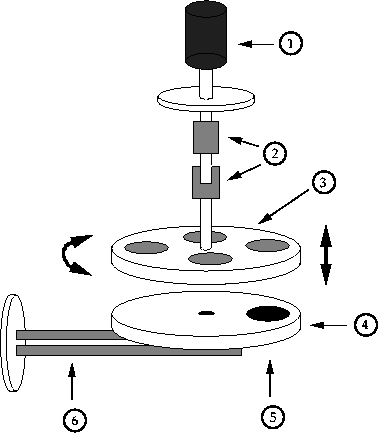

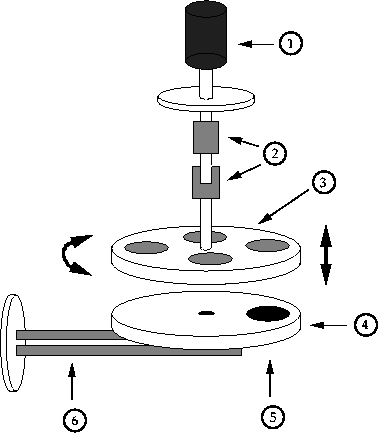

A schematic drawing of the system is shown in Figure 1. The

stationary tray is supported by aluminum rods (not shown). In

order to provide maximum thermal isolation for the two trays,

the support rods are insulated from the stationary tray by

ceramic washers and the moving tray is connected to the

universal joint via a teflon rod. On the underside of the

stationary tray, a thermocouple attached to a ceramic post

presses against the moving tray through a hole in the

stationary tray. This thermocouple provides an approximate

measurement of the substrate temperature. Another

thermocouple (not shown) is mounted on the stationary tray

itself.

Experience has shown that the stationary tray reaches a

temperature of 100K after running liquid nitrogen for 35

minutes, while the moving tray reaches a final temperature of

120K after 45 minutes. This cooling is adequate to allow

deposition of Fe/Ge multilayers with good magnetic and

structural properties.[1]

Part of this work was performed under the auspices of the

U.S. Department of Energy by LLNL under contract No.

W-7405-ENG-48.

1. A. Chaiken and R.P. Michel, unpublished.

Figure 1: Schematic drawing of the

cryogenically cooled multiple substrate holder. The major

components are: 1) the linear/rotary motion feedthrough; 2)

the universal joint which allow rotary motion around

orthogonal axes, making thermal contact of the plates

insensitive to their relative alignment; 3) the moving

substrate tray; 4) the stationary cryogenically cooled tray;

5) the aperture in the stationary tray through which

deposition occurs; and 6) the cryogen lines. Both the motion

and cryogen feedthroughs are mounted on 2 3/4" copper-gasket

flanges. The material is OFHC copper for the trays and the

cooling lines. The universal joints and support rods

connecting them are made of aluminum except for one support

rod which is made of teflon in order to maximize thermal

isolation.

Online Physics Papers

Online Physics Papers

alchaiken@gmail.com

(Alison Chaiken)

Fri Nov 24 13:11:42 PST 1995